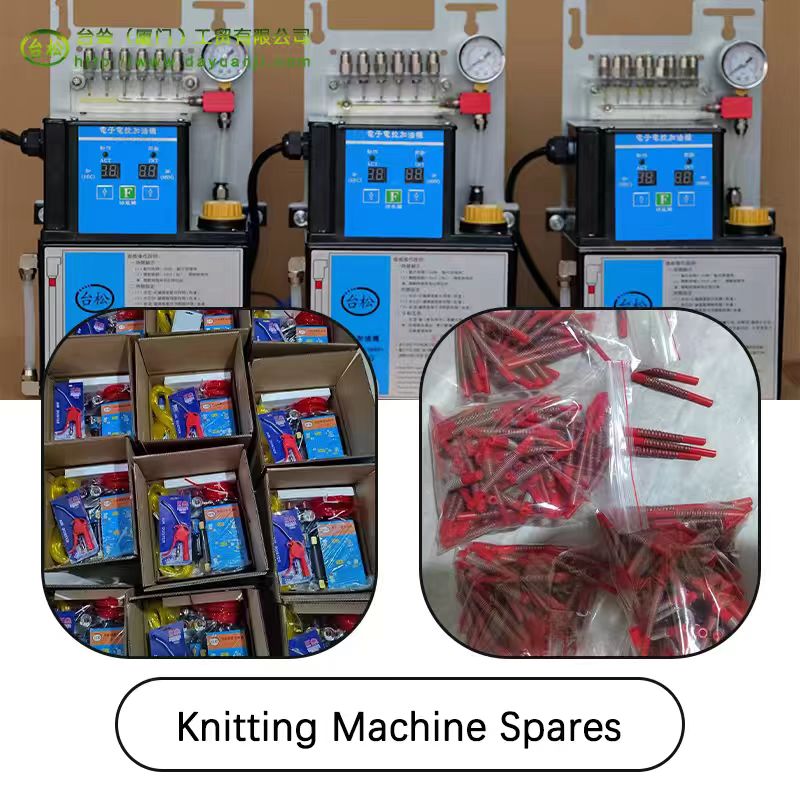

Product Introduction of Electronic Oil Lubricator for Circular Knitting Machines

Product Overview

This electronic oil lubricator for

circular knitting machines is an intelligent lubrication device specially developed for the weaving process of large

circular knitting machines, which accurately meets the lubrication needs of key moving parts such as needle beds, cam tracks and sinkers of various

circular knitting machines. Compared with the traditional manual oiling or mechanical timed oiling modes, the device adopts digital control technology to realize on-demand, quantitative and fixed-point automatic lubrication, which effectively solves the industry pain points such as uneven lubrication, grease waste and excessive component wear, and provides reliable guarantee for knitting production enterprises to improve equipment operation stability and extend machine service life.

Core Advantages

1. Intelligent and Precise Volume Control

Equipped with a high-precision microcomputer control system, it can freely set the single oiling volume (adjustable from 0.01 to 0.5ml) and oiling interval (settable from 1 to 999 minutes) according to parameters such as the rotating speed of the

circular knitting machine and the type of woven fabric. It ensures that every lubrication point is supplied with just the right amount of grease, avoiding fabric contamination caused by excessive grease or component jamming and damage due to insufficient lubrication.

2. Efficient Automatic Operation

It supports linked start-stop with the

circular knitting machine, and the device can automatically identify the operating status of the main machine, supplying oil synchronously when starting up and stopping automatically when shutting down, without manual on-duty. Equipped with a large-capacity oil storage tank (optional capacity of 1L/2L/3L), it reduces the frequency of frequent oil replenishment operations, greatly lowers labor costs and improves workshop production efficiency.

3. Stable, Durable and Strong Adaptability

The fuselage is made of high-strength aluminum alloy material, with dust-proof, oil-proof and corrosion-resistant properties, which can adapt to the harsh high-temperature and high-humidity environment of knitting workshops. The oil outlet pipeline is made of high-pressure and wear-resistant hoses, matched with quick-plug joints, featuring convenient installation and excellent sealing performance, which effectively prevents oil leakage failures. The device is compatible with various knitting special lubricating oils such as mineral oil and synthetic oil, and is suitable for large

circular knitting machines of different brands and models.

4. Convenient Maintenance and Fault Early Warning

Equipped with a high-definition LED display screen, it displays key data such as oiling volume, oiling interval and remaining oil volume in real time. The operation interface is simple and intuitive, which can be easily mastered by ordinary workers. Built-in fault early warning systems for insufficient oil volume and pipeline blockage, it will automatically send out sound and light alarms once abnormalities occur, reminding staff to handle them in a timely manner and avoiding production interruption caused by lubrication failures.

Application Scenarios

It is widely applicable to the lubrication system transformation and new installation of various knitting equipment such as single-jersey

circular knitting machines, double-jersey

circular knitting machines, rib machines and fleece machines. It can meet the production process needs of various knitted products such as underwear, T-shirts, sweaters and sportswear fabrics, and is an ideal choice for knitting factories to realize intelligent equipment upgrading and reduce production costs.

Circular knitting machine, knitting machine accessorieshttp://www.dayuanji.com

comments list

I want to comment